The Importance of Heavy Machinery in Construction, Mining, and Road-Building Projects

Heavy and industrial machinery plays a vital role in executing large-scale construction, mining, and road-building projects. These specialized machines are designed to enhance speed, precision, and overall efficiency. In this article, we will introduce 30 types of heavy machinery and their specialized applications.

Categories of Heavy Machinery

Heavy machinery is generally divided into three main categories:

- Construction Machinery

- Road-Building Machinery

- Mining Machinery

Each category includes equipment designed for specific tasks. Below, we’ll take a closer look at the most important machinery in these areas.

Introduction to Construction Machinery and Their Applications

1-Bulldozer

A bulldozer is a powerful machine designed for leveling land, moving soil, and clearing surfaces. It is commonly used in excavation and road-building projects. This machine, also known as a crawler tractor, moves using tracks and is equipped with a steel blade at the front. The blade can handle large volumes of materials such as snow, soil, sand, gravel, debris, and more during operation.

The term "bulldozer" is sometimes used as a general name for various types of heavy engineering machinery.

2-Excavator

An excavator, equipped with a long arm and a digging bucket, is used for digging, excavation, and building demolition. This heavy construction and engineering machine features an articulated arm, a bucket, a rotating cabin, and tracks or rubber wheels. It is a modern version of the old steam shovels.

Excavators can be fitted with various tools such as hydraulic hammers, drills, metal shears, and grapples. For example, when equipped with a hydraulic hammer, they can demolish rocks and concrete that are difficult to break with explosives or compressors.

For soft soils and large volumes of material, loaders are a more cost-effective option. However, in urban construction, excavators are preferred due to their high maneuverability and minimal impact on surrounding areas.

3-Loader

A loader is used for loading various materials like soil, sand, and gravel onto trucks. It is a versatile machine widely used in road construction and building projects and comes in two main types: rubber-tired and track loaders. Leading companies such as Caterpillar, Komatsu, Volvo, Hepco, Hitachi, and Kawasaki manufacture loaders.

Loaders are among the most practical construction and civil engineering machines. Available in various sizes, their high functionality and flexibility make them capable of performing many tasks by simply changing the bucket. Some common uses of loaders include:

- Building embankments

- Excavating foundations

- Filling trenches

- Backfilling around pipelines laid in canals

- Loading trucks

- Transporting concrete to molds

- Lifting and carrying construction materials

Additionally, loaders can be equipped with various attachments such as snowplows, trenchers, pipe cutters, pipe layers, cranes, and forklifts, further expanding their range of applications.

4- Backhoe Loader

A backhoe loader is a multifunctional machine capable of both digging and loading. This self-propelled tractor combines a backhoe (digging bucket) on the rear and a loader bucket on the front. Designed for lighter tasks, its general features resemble those of loaders and excavators. Due to its dual functionality, it is widely used in smaller projects, particularly in construction and civil engineering.

Backhoe loaders come in various sizes and models, from compact to large, making them suitable for farms and diverse projects. The name "backhoe loader" originates from combining the terms "backhoe" and "loader."

To enhance the machine's performance and capabilities, additional features are often included, such as:

- Multi-purpose front buckets

- Telescopic rear booms

- Four-wheel drive (4WD) for the front axle

- Sliding side-shift capabilities

- Differential locks

- Driver-friendly cabins equipped with comfort features

- Shuttle or Power Shift transmissions

5-Roller

A roller is a machine used for compacting soil and asphalt in road construction and building projects. Rollers are commonly utilized in road construction, landfill sites, and agricultural works.

In the construction industry, rollers are essential for compressing gravel, concrete, asphalt, and soil. Their primary purpose is to create smooth, solid surfaces, ensuring that the final surface is prepared accurately and with precision.

6- Jackhammer

A jackhammer is used for breaking concrete and rocks in both small and large construction projects. This pneumatic or electromechanical tool combines a hammer and a chisel and is commonly known as a demolition hammer. Invented by William Mcreavy, the patent was later sold to Charles Brady King.

Handheld jackhammers typically operate with compressed air, though some are powered by electric motors. Larger jackhammers, often mounted on construction machinery, usually function hydraulically. These tools are widely used for breaking rocks, asphalt, and concrete.

A jackhammer operates by moving an internal hammer up and down. First, the hammer moves downward, striking the chisel, and then returns to its original position to repeat the cycle. The tool’s efficiency depends on the amount of pressure applied during operation.

Although commonly used in construction for breaking hard surfaces, jackhammers are not classified as excavation machinery. Accessories like pressure bases and lubricators also contribute to their performance.

7- Paver (Asphalt Finisher)

A paver is used for spreading asphalt on roads and large surfaces. This heavy road construction machine is essential for preparing and leveling the surface of roads, sidewalks, bridges, parking lots, and similar areas. The paver distributes asphalt concrete or similar materials evenly over the desired surface while providing initial compaction. After this, a roller is used to ensure final compaction and smoothness.

The paver works by receiving asphalt or concrete from material transport trucks and spreading it across the surface with a thickness, length, and width set by the operator. These surfaces typically include roadbeds, parking lots, and other large spaces. Once the paver completes its task, a roller follows to compact and smooth the material, ensuring a solid and even finish.

At the rear of the paver, there is a hopper where trucks unload their materials. At the front, a wide plate called the "screed" spreads the material evenly across the surface, ensuring uniformity and precision in the final result.

8- Grader

A grader is used to level and adjust road surfaces, preparing them for asphalt paving. Known as a slope maker, the grader is a heavy engineering machine designed for smoothing and leveling road and soil surfaces. It is equipped with a large blade used for precise slope adjustment and soil grading. Most grader models have three axles, with the engine and cabin positioned on the rear axle at the back of the machine.

This machine is one of the primary tools for slope adjustment, embankment leveling, soil excavation, and bringing the surface to the desired height and alignment according to project specifications.

Applications and Operations of Graders:

- Spreading and distributing soil materials

- Distributing materials in road shoulder construction

- Precise grading and leveling of surfaces

9- Cold Planer

A cold planer is a specialized machine in the road construction industry used for removing and resurfacing asphalt and concrete surfaces. It operates with a high-speed rotating blade that precisely and evenly strips the top layers of the road or street surface. Cold planers are primarily used for road recycling, repairing damaged or old surfaces, and preparing the surface for new layers of material.

Due to its high efficiency and accuracy in material removal, this machine is widely used in road construction and urban street resurfacing projects. One important feature of the cold planer is its ability to recycle the removed materials, allowing them to be reused in the construction of new roads.

10- Dumper

A dumper is a versatile and practical vehicle commonly used in construction, mining, and road-building projects. It is specifically designed for transporting bulk materials over short distances. This machine typically features a large, durable body with the ability to unload materials either automatically or manually. Thanks to its high carrying capacity and powerful engine, the dumper performs efficiently and quickly, even in challenging work environments.

Features and Uses of a Dumper

- Transporting Heavy Materials: Ideal for moving sand, gravel, soil, rocks, and other construction materials.

- Adaptability to Different Conditions: Wheel dumpers are suitable for flat and paved roads, while track dumpers are designed for rough and uneven terrains.

- Wide Range of Applications: Used in construction, mining, and even during emergencies to move materials in tough conditions.

- Improved Efficiency: The quick and easy unloading system reduces the time and cost of construction operations.

Types of Dumpers

- Wheel Dumpers: Perfect for material transportation on smooth and paved roads.

- Track Dumpers: Designed for challenging terrains and operations requiring greater stability.

11- Dump Truck

A dump truck is a large vehicle designed to transport significant amounts of soil, minerals, and other materials in mines and large-scale projects.

The dump truck is one of the heavy-duty machines used for transporting and unloading various materials such as soil, sand, gravel, rocks, construction materials, and industrial waste. It is equipped with a large tiltable bed that can be raised automatically or manually to unload its contents. Dump trucks are widely used in industries like construction, mining, road building, and other major projects.

Types of Dump Trucks

- Standard Dump Trucks: These are suitable for transporting materials on smooth and paved roads.

- Off-Road Dump Trucks: Specially designed for rough terrains, these trucks have large, durable wheels and are built to handle heavy loads in challenging environments.

Why Use Dump Trucks?

- High Capacity: They can carry large volumes of materials in a single trip.

- Efficiency: Quick loading and unloading save time on large projects.

- Durability: Built to perform effectively in harsh and demanding conditions.

12- Drilling Rig

A drilling rig is a heavy and complex machine used for drilling into the earth to extract underground resources like oil, gas, water, and minerals. These machines are widely utilized in the oil and gas industry, mining, and water supply projects. Drilling rigs can penetrate deep into the ground and, with specialized drill bits, extract materials from significant depths.

Key Features

Drilling rigs typically consist of the following components:

- Engine: Provides the power for the machine.

- Hydraulic Systems: Control the movement and operation of the rig.

- Drilling Tower: Supports the drill pipes and equipment during operation.

- Feed and Bit Support Systems: Ensure the drill bit is properly maintained and fed into the ground.

- Control Equipment: Allows operators to monitor and adjust the drilling process.

Types of Drilling Rigs

- Onshore Drilling Rigs: Designed for drilling on land, commonly used for extracting resources like oil and gas.

- Offshore Drilling Rigs: Built to operate in seas and oceans, specifically for extracting oil and gas from underwater fields.

Importance

Drilling rigs play a crucial role in accessing underground resources, enabling the development of industries and infrastructure. With their ability to drill deep and complex wells, they are an essential tool in industrial drilling operations.

13- Shovel

A shovel is a heavy-duty machine designed for excavating, moving, and loading various materials such as soil, rocks, sand, gravel, and minerals. Shovels are widely used in construction, road-building, mining, and infrastructure projects. Due to their high power and fast loading capacity, they are considered essential equipment in these industries.

Types of Shovels

- Mechanical Shovels: Operate using mechanical systems like cables and pulleys, making them suitable for material loading and unloading.

- Hydraulic Shovels: Use hydraulic systems to move materials, offering greater precision and efficiency. These are often used in more demanding and heavy-duty projects.

Key Features and Applications

Shovels are highly effective for operations involving the movement of large quantities of materials. They are particularly vital in mining and large-scale construction projects due to their powerful digging capabilities and high loading capacity. These machines are indispensable tools for industries requiring heavy material handling.

14- Drill Wagon

A drill wagon is a heavy-duty machine used for drilling in large-scale mining, construction, and road-building projects. These machines are specifically designed for wide-area drilling, creating vertical or horizontal wells, and are commonly used for blasting operations or excavation in mining and infrastructure projects. Drill wagons are equipped with complex hydraulic, mechanical, and electrical systems to perform deep drilling tasks.

Key Components of Drill Wagons

- Drilling System: Includes drills, drilling pipes, and feeding systems for the drill.

- Hydraulic and Mechanical Systems: Used for moving the machine and carrying out deep drilling operations.

- Fixed or Moving Wagon: The machine is mounted on a fixed or movable wagon, allowing for mobility during operations.

Applications and Benefits

Drill wagons are particularly useful for projects requiring deep and extensive drilling, such as stone, oil, gas mines, and large-scale construction projects. They can drill with high precision and speed in various environments, making them essential tools for large industrial drilling operations.

15- Scraper

A scraper is a heavy-duty machine used for digging, transporting, and leveling soil, stone, and various materials. This machine is commonly used in road construction, dam building, mining, and other civil engineering operations. Due to its ability to move large quantities of material, it is a useful tool in large-scale projects.

How Scrapers Work

Scrapers are equipped with a large, adjustable blade that can dig materials from the ground surface and collect them into a loading container or compartment. The materials are then transported to the designated location. Scrapers are generally divided into two types:

- Towed Scrapers: These are pulled by tractors or towing machines and are used for medium-scale operations.

- Self-Propelled Scrapers: These scrapers have their own engines and can move independently. They are typically used in large, complex projects that require high mobility and efficiency.

Applications and Benefits

Due to their high power in moving and leveling materials, scrapers are highly effective in heavy-duty projects, especially in large and uneven terrain. They play a significant role in reducing project time and costs and are essential for improving the quality of ground leveling.

16- Tower Crane

A tower crane is a type of crane commonly used in large construction projects, especially in the construction of tall buildings and urban projects. This device is known for its unique design, which includes a fixed tower, a horizontal arm, and a control cabin, allowing it to lift and move heavy loads at great heights and in confined spaces.

Components of Tower Cranes

Tower cranes typically consist of two main parts:

- Tower: This is the tall, fixed part on which the crane sits. Its height can be significantly increased to reach the desired elevation.

- Jib (Horizontal Arm): Attached to the tower, this arm is responsible for lifting and moving loads horizontally. It can typically rotate to move loads to different areas.

Applications and Benefits

Tower cranes are ideal for large construction projects and tall buildings due to their ability to lift heavy loads at great heights. They also play an important role in increasing the efficiency of construction projects due to their high precision in load movement and speed. These cranes are especially useful in confined spaces where access for larger machinery is difficult, and they are highly beneficial in building structures in high-rise areas or cities with heavy traffic.

17- Forklift

A forklift is an industrial vehicle designed to move and transport heavy and bulky loads in confined spaces. This machine features two forks at the front, which allow it to lift and move loads at various heights. Forklifts are commonly used in warehouses, factories, distribution centers, and other industrial environments for handling goods and materials.

Types of Forklifts

Forklifts are generally divided into two main types:

- Electric Forklifts: These forklifts operate using batteries and are ideal for indoor environments where low pollution and minimal noise are required.

- Fuel Forklifts: These forklifts operate using fossil fuels like diesel or propane and are typically used for outdoor environments or larger spaces.

Key Features and Applications

Important features of forklifts include their ability to lift heavy loads, high maneuverability in tight spaces, and capability to handle loads of various sizes. These machines greatly enhance productivity in warehouses and various industries, assisting with the movement of goods and materials on the ground, on shelves, and at different heights. Forklifts play a crucial role in speeding up warehouse operations and product distribution due to their fast movement and precision in handling loads.

18- Telescopic Handler

19- Shotcrete Machine

A shotcrete machine is a specialized device used for spraying mortar or concrete onto surfaces at high speed and pressure. This machine is typically used in construction projects, tunneling, dam construction, structural reinforcement, and even in swimming pool and spa projects. The shotcrete process involves spraying concrete or mortar through pressure hoses onto the desired surface to create a strong and smooth layer.

Types of Shotcrete Machines

- Dry Mix Shotcrete: In this method, dry materials (cement, sand, and additives) are mixed in a mixer and then sprayed through pressure hoses. Water is added at the spraying location.

- Wet Mix Shotcrete: In this method, all materials (cement, water, and additives) are pre-mixed and then sprayed through pressure hoses onto the surface.

Key Features of Shotcrete Machines

- High Speed: The spraying process is faster than traditional concrete pouring methods.

- High Strength: Layers created using shotcrete are strong and durable.

- Suitable for Hard-to-Reach Areas: Shotcrete machines are particularly useful for covering surfaces that are difficult to access directly, such as tunnels and underground structures.

- Flexibility in Project Execution: This machine can be used for various types of projects, including reinforcement, concrete repair, and the construction of specialized structures.

Efficiency

Due to its time-saving, cost-effective, and quality-enhancing benefits, the shotcrete machine is highly popular in large construction and engineering projects.

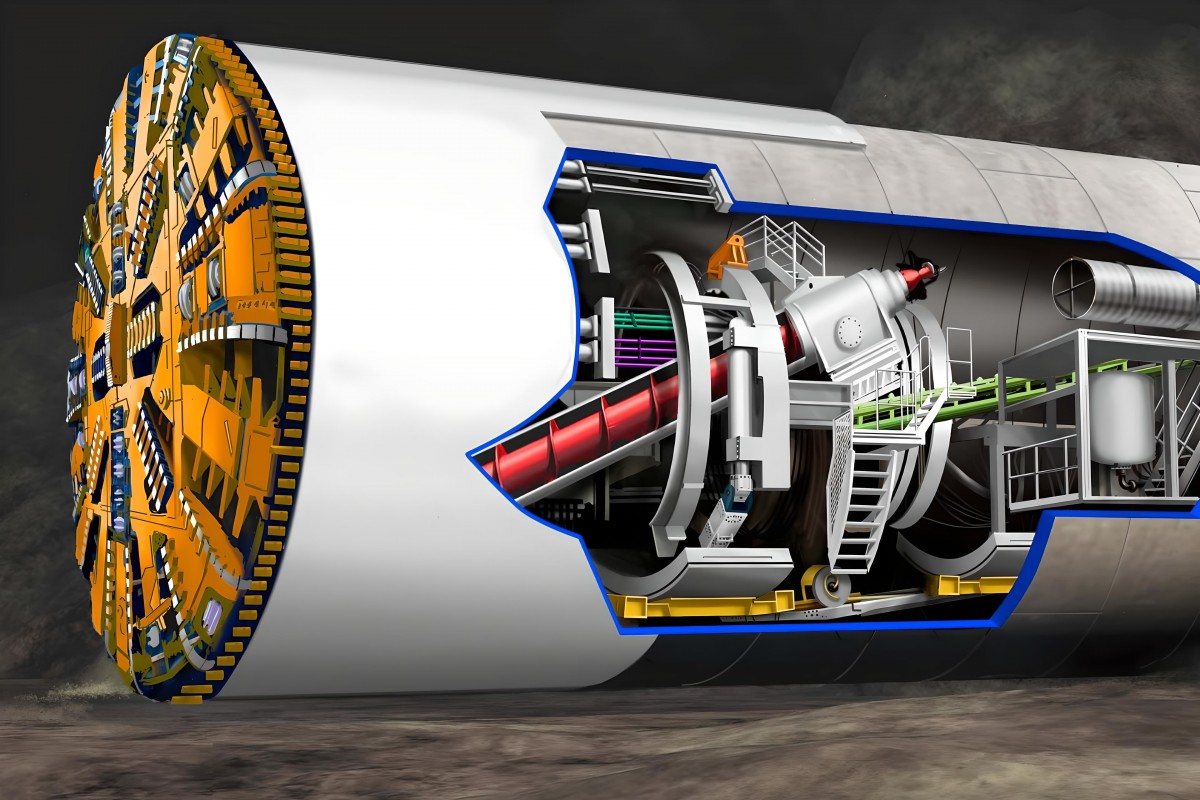

20- Tunnel Boring Machine - TBM

The Tunnel Boring Machine (TBM) is a complex device used for drilling tunnels in underground projects like metro lines and roads. It drills through the ground with its rotating cutter head, creating tunnels of varying diameters and depths.

Features:

- Cutter Head: The front part that drills through different types of ground.

- Advancement System: The machine moves forward after drilling.

- Excavated Material Removal: Transporting the soil with various systems.

- Tunnel Structure: Installing supports and concrete segments during drilling.

Benefits:

- High drilling speed.

- Reduced tunnel collapse risks.

- Minimal disruption to the surface.

TBMs are highly effective for complex underground projects, especially in urban areas.

21- Combine Harvester

The Combine Harvester is an advanced agricultural machine used for harvesting crops like wheat, barley, rice, corn, and other grains. It combines multiple agricultural processes, including harvesting, threshing, separating grains from chaff, and collecting the grains simultaneously.

Key features of a Combine Harvester:

- Header: The front part that cuts and gathers the crop.

- Separation System: Separates the grains from the chaff and transfers them to the storage chamber.

- Cleaning System: Removes excess material like chaff and leaves, leaving clean grains in the storage.

- High Capacity: Due to its large size and efficient systems, it can harvest large amounts of crops in a short time.

Combine harvesters play a crucial role in modern agriculture by significantly increasing the speed and accuracy of crop harvesting, reducing the need for manual labor, and saving time and costs. They enhance productivity by performing several harvesting tasks simultaneously.

22- Side Boom

A Side Boom is a heavy machinery used in pipeline installation and laying large, heavy pipes in projects related to oil, gas, petrochemical, and similar industries. It is designed to place heavy pipes accurately in various positions on or near the ground surface.

Key features of a Side Boom:

- Long Boom Arm: Allows the machine to move heavy pipes and position them at low heights or ground level.

- Hydraulic System: Typically utilizes hydraulic systems for lifting and moving pipes, providing the necessary power to handle heavy loads.

- Pipeline Installation: Side booms are used to move and install pipes, especially in underground pipeline projects or challenging environments, without damaging the pipe structure.

Side booms are especially useful in large-scale pipeline projects where heavy pipes need to be moved and installed in uneven terrain or specific locations. They help reduce installation time and increase accuracy in pipeline projects.

23- Asphalt Roller

An Asphalt Roller is a heavy machine used for compacting and leveling asphalt layers in road construction and paving projects. It uses the weight and rotation of its rollers to compress the asphalt and provide a smooth, uniform surface for roads or streets.

Key features of an Asphalt Roller:

- Steel or Rubber Rollers: Asphalt rollers are typically made from steel or rubber, each suitable for different types of asphalt and work conditions. Steel rollers are used for compacting the initial asphalt layers, while rubber rollers are used for final compaction.

- Compaction System: The machine compresses the asphalt using its heavy weight and pressure, improving road quality and increasing the asphalt's lifespan.

- Adjustable Weight: Many rollers have adjustable weight systems to optimize compaction based on project needs.

- Movement Type: Some rollers can move forward and backward, making it easier for operators to maneuver on various projects.

Asphalt rollers are used in road, street, airport, and other infrastructure projects. They not only help compact and level the asphalt but also improve the road surface quality, prevent cracking, and extend the lifespan of the asphalt.

24- Mini Loader

A Mini Loader is a compact, heavy-duty machine used for moving and transporting various materials in small to medium-sized projects. Similar to larger loaders but with smaller size and lower power, it is ideal for working in tight spaces and on projects with less intensive workloads.

Key features of a Mini Loader:

- Compact Size and High Maneuverability: Due to its small size, mini loaders can move through confined and winding spaces, making them perfect for projects with limited space such as gardens, small buildings, and urban sites.

- Versatility: These machines are often equipped with a variety of attachments such as forks, buckets, grapples, and other specialized tools, allowing them to perform different tasks.

- Hydraulic System: Mini loaders use a hydraulic system to operate their arms and attachments, enabling them to perform tasks like digging, material handling, and loading.

- Use in Urban and Confined Spaces: Their compact design allows them to work in urban environments or on limited land areas while handling heavy tasks efficiently.

Mini loaders are widely used in projects such as excavation, material handling, agricultural tasks, and small-scale road construction. Due to their high flexibility and ability to be equipped with various tools, they are considered efficient and versatile machines for many projects.

25- Laser Grader

A Laser Grader is an advanced machine used for precise leveling and smoothing of soil, asphalt, or concrete surfaces. It utilizes laser technology to automatically adjust the ground level, ensuring that unevenness and improper slopes are avoided. Laser graders are typically employed in large-scale construction projects, road building, airports, and industrial infrastructure.

Key features of a Laser Grader:

- High Precision with Laser Technology: The machine uses laser receivers and systems mounted on both the device and the ground surface, allowing it to adjust the ground level with millimeter precision. This feature is particularly important in projects that require high accuracy in surface grading.

- Automatic Operation: The laser system enables the machine to make automatic adjustments, reducing the need for operator intervention. This enhances both the speed and precision of the operation.

- Advanced Hydraulic System: The laser grader uses hydraulic systems to control the blade's movements, enabling precise adjustments to the surface in any direction.

- Use in Sensitive Projects: This device is ideal for projects that require exact leveling, such as airport construction, roadwork, and parking lots that need to be perfectly flat and uniform.

Due to its high accuracy, fast performance, and reduced need for manual labor, the laser grader is widely used in large construction and infrastructure projects. It improves the quality of surface grading while reducing project time and costs.

26- Skip Loader

A Skip Loader is a type of heavy machinery used for transporting and moving materials in construction and civil engineering projects. This device combines the functions of a loader and a truck, typically featuring an interchangeable bucket at the front and a transport section at the rear.

Key features of a Skip Loader:

- Interchangeable Bucket: The skip loader is equipped with a bucket at the front, which can be used for transporting various materials such as soil, rocks, construction debris, or other materials.

- Transport System: At the rear of the device, it usually has another bucket or transport section that enables the easy transfer of materials from one point to another.

- Easy Movement and Efficiency in Tight Spaces: Due to its medium size and compact design, the skip loader can easily maneuver in tight and winding spaces, making material handling efficient in confined areas.

- Versatility: This machine is typically equipped with various attachments, such as forks, jacks, and different buckets, for performing a range of tasks. This makes the skip loader a versatile tool for construction and engineering projects.

Skip loaders are highly valued for their efficiency, versatility, and high maneuverability. They are commonly used in projects like road construction, material transportation in building sites, excavations, and handling construction waste. Due to their ability to quickly and easily move materials in tight spaces, they are a popular choice for small to medium-sized projects.

27- Block Placing Machine

A Block Placing Machine is a specialized device used for placing stone, concrete, or similar materials in construction and civil engineering projects. It's typically employed in projects such as building block walls, paving surfaces, and similar infrastructure, helping to speed up and improve accuracy in the block placement process.

Key features of a Block Placing Machine:

- Automatic or Semi-Automatic System: Block placing machines are often designed with automatic or semi-automatic systems, allowing operators to place blocks more quickly and accurately at designated locations.

- High Accuracy: The machine can place blocks precisely at specific heights and positions, reducing errors in construction and increasing work efficiency.

- Block Handling Capability: The machine can easily transport and place stone or concrete blocks from one location to another. It is usually equipped with a transport or crane system for this purpose.

- Ideal for Large Projects: These machines are typically used in large projects such as building tall walls or large surfaces, automating the process of block placement to reduce manual labor.

The Block Placing Machine has become an essential tool in construction and civil engineering projects due to its ability to reduce the need for manual labor, improve speed, and ensure precision in block placement. It is particularly effective in projects requiring the placement of large numbers of blocks in a short time, leading to savings in both cost and time.

28- Concrete Pump Truck

A Concrete Pump Truck is a heavy-duty machine used to transfer ready-mix concrete to hard-to-reach locations or areas with difficult access. This device is commonly used in construction and civil engineering projects to pump concrete to higher floors or challenging spots. The concrete pump includes a hose or pipe that transports concrete from the mixer to the desired location.

Key features of a Concrete Pump Truck:

- Hydraulic System: The Concrete Pump Truck uses a hydraulic system to pump concrete, providing the necessary power to move the concrete from the mixer to the construction site. This system is capable of transferring concrete over long distances and to higher elevations.

- Flexible Boom: One of the standout features of the concrete pump is its adjustable, flexible boom that can be positioned easily to access difficult areas. This boom allows the operator to direct the concrete exactly where it's needed.

- Fast and Precise Pumping: Due to its specialized design, the Concrete Pump Truck can transfer concrete quickly and precisely, improving project speed and reducing the time needed for concrete distribution.

- Long-Distance Concrete Transport: This machine is highly effective for projects requiring the pumping of concrete over long distances or to elevated heights. It is commonly used in the construction of tall buildings, bridges, dams, and large infrastructure projects.

Concrete Pump Trucks are invaluable in construction and civil engineering projects for pumping concrete to upper floors, hard-to-reach spots, and long distances. These machines help increase work speed, reduce labor costs, and shorten project timelines by efficiently transporting concrete in various conditions.

29- Crawler Loader

A Crawler Loader is a type of heavy machinery that combines the functions of a loader and a bulldozer, specifically designed for moving materials and soil in construction and mining projects. Unlike traditional wheel loaders, a Crawler Loader uses tracks (crawler chains) instead of rubber wheels, allowing it to move through rough, muddy, and sloped terrains with ease.

Key features of a Crawler Loader:

- Crawler Chains: Unlike regular wheel loaders, the Crawler Loader uses steel tracks for movement. This feature enhances the machine's stability on soft, muddy, and swampy ground, preventing it from sinking into the soil.

- High Power and Efficiency on Rough Terrain: Due to its heavy weight and powerful engine, the Crawler Loader can move heavy materials and soil even in tough conditions. This makes it ideal for construction, mining, and even excavation projects.

- Long Boom and High Maneuverability: The machine is typically equipped with a highly maneuverable arm that allows it to easily scoop materials from the ground and move them to different locations. The boom's ability to adjust and change angles makes excavation and material handling easier and more efficient.

- Used in Heavy Projects: The Crawler Loader is particularly suited for projects requiring movement on uneven or difficult terrain, such as road construction in mountainous areas or mining operations.

Crawler Loaders are highly effective in projects that require moving materials over rough, sloped, or tough terrains. With their high maneuverability and track system, these machines resist wear and tear caused by harsh ground conditions, improving the speed and accuracy of operations.

30- Gantry Crane

A Gantry Crane is a type of crane designed for lifting and moving heavy loads in open spaces or industrial environments. Its unique design, which features two legs and a frame at the top, allows it to move along the ground or specialized rails. Gantry cranes are commonly used in various industries, including ports, factories, warehouses, and construction projects.

Key features of a Gantry Crane:

- Gantry Design: The crane is designed to lift loads using a horizontal frame (the gantry) and move them horizontally in both directions. This design allows the crane to operate in large open areas with ease.

- Heavy Load Handling Capacity: Gantry cranes are capable of lifting very heavy loads, including large components, industrial equipment, containers, and construction materials.

- Horizontal and Vertical Movement: These cranes usually have both horizontal and vertical movement capabilities. With specialized rail systems, the gantry crane can move loads across the ground or specific surfaces.

- Use in Industrial and Port Projects: Gantry cranes are especially useful in ports for handling containers, in factories for moving heavy components, and in construction projects for lifting heavy materials and equipment.

- High Stability and Safety: Due to their robust design and high stability, gantry cranes can safely handle heavy loads without compromising on safety.

Gantry cranes are highly effective in industries requiring heavy load handling, large working spaces, and high operational efficiency. Their versatility and strength make them ideal for projects that involve the movement of heavy and large items.