Gantry cranes are powerful lifting systems designed to handle heavy loads with precision and efficiency. From towering cranes used in shipping ports to compact versions found in workshops, gantry cranes have revolutionized material handling across various industries. Their versatility, mobility, and ability to adapt to specific tasks make them indispensable tools in construction, manufacturing, logistics, and beyond. In this article, we’ll delve into everything you need to know about gantry cranes—how they work, their types, unique features, and their applications—providing you with a complete understanding of these essential machines.

What is a Gantry Crane?

A gantry crane is a type of crane that operates atop a gantry, a structure designed to straddle a workspace or object. Gantry cranes vary in size and capacity, from small shop cranes used for tasks like lifting car engines to large-scale industrial gantry cranes capable of handling loads weighing hundreds of tons, such as shipping containers or massive industrial equipment.

They are also called portal cranes because of the open "portal" or space beneath the gantry structure that allows objects to be moved in and out freely.

Key Features of Gantry Cranes

- Mobility: Gantry cranes are often mounted on wheels or rails, allowing the entire structure to move freely along a designated path.

- Versatility: They can handle a wide variety of loads, from lightweight components to extremely heavy machinery.

- Adjustable Height: Many gantry cranes offer adjustable heights, making them suitable for different types of tasks and environments.

- Customizable Design: Gantry cranes can be tailored to specific needs, including span length, lifting capacity, and mobility options.

Types of Gantry Cranes

Gantry cranes are classified based on their design, application, and capacity:

1. Full Gantry Cranes

These are the largest gantry cranes, commonly used in shipyards, container terminals, and heavy industries. They can lift some of the heaviest loads in the world, making them ideal for moving shipping containers and heavy industrial equipment.

2. Semi-Gantry Cranes

A semi-gantry crane has one side supported by legs on rails, while the other side is attached to a fixed structure such as a building. This design saves space and is commonly used in warehouses or smaller industrial environments.

3. Portable Gantry Cranes

These smaller gantry cranes are lightweight and designed for mobility. They are often used in workshops for lifting smaller loads, such as engines or components.

4. Adjustable Gantry Cranes

These cranes have adjustable height and span, making them versatile and suitable for a range of applications. They are particularly useful when working with varying load sizes.

5. Rubber-Tired Gantry Cranes (RTGs)

RTGs are mobile gantry cranes equipped with rubber tires instead of rails, allowing them to operate in open spaces without fixed tracks. They are often used in container yards.

How Do Gantry Cranes Work?

A gantry crane consists of several components:

- Gantry Structure: The main frame that supports the crane and provides mobility.

- Hoist: The lifting mechanism that raises and lowers loads, typically powered by an electric or hydraulic motor.

- Trolley: The hoist is mounted on a trolley that moves horizontally along a beam, enabling precise positioning of the load.

- Rails or Wheels: Depending on the type of gantry crane, the structure may move along rails or rubber tires.

The combination of these components allows gantry cranes to lift, move, and position heavy loads efficiently.

Gantry Cranes vs. Overhead Cranes

The terms gantry crane and overhead crane are often used interchangeably, but they have distinct differences:

| Feature | Gantry Crane | Overhead Crane |

|---|---|---|

| Mobility | Entire structure is mobile (on wheels/rails). | Fixed structure, supported by walls/ceiling. |

| Supporting Structure | Freestanding gantry frame. | Building walls or ceiling beams. |

| Applications | Outdoor and indoor use. | Mostly indoor use. |

Interestingly, some cranes blur the lines between these two categories. For example, some gantry cranes incorporate an overhead beam with a hoist, while certain overhead cranes can be mounted on a freestanding gantry structure.

Applications of Gantry Cranes

Gantry cranes are incredibly versatile and are used in various industries, including:

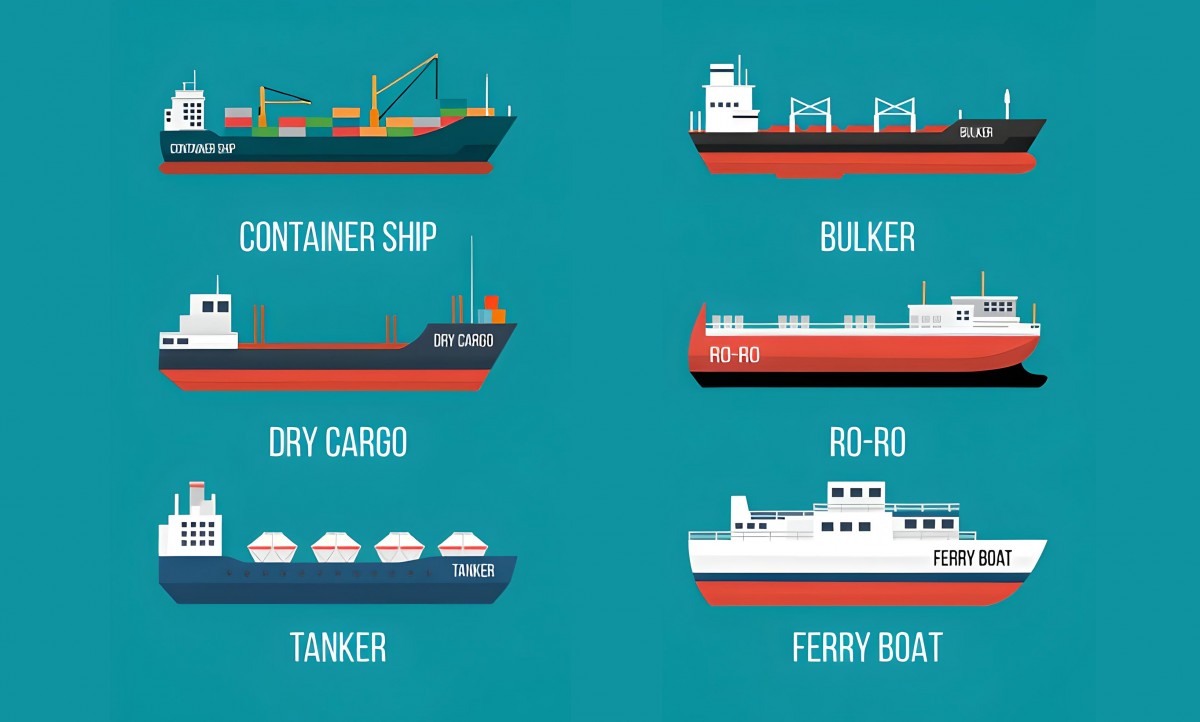

- Shipping and Ports: Handling shipping containers, loading/unloading cargo ships.

- Construction: Lifting heavy materials like steel beams and concrete blocks.

- Manufacturing: Moving large machinery and components in factories.

- Warehousing: Organizing and transporting goods in storage facilities.

- Rail Yards: Lifting and moving train components or cargo.

Advantages of Gantry Cranes

- High Load Capacity: Capable of handling extremely heavy loads.

- Cost-Effective: More affordable than permanent crane installations like overhead cranes.

- Portability: Easily moved between workspaces, depending on the type.

- Durability: Built to withstand harsh environments, especially in outdoor applications.

- Flexibility: Customizable for specific tasks, industries, and environments.

FAQs About Gantry Cranes

1. What is the maximum load capacity of a gantry crane?

The load capacity varies by type and design. Smaller portable gantry cranes may handle loads under 5 tons, while full gantry cranes in ports can lift hundreds of tons.

2. Are gantry cranes suitable for indoor use?

Yes, many gantry cranes, especially semi-gantry and portable types, are ideal for indoor applications like factories and warehouses.

3. What maintenance is required for gantry cranes?

Regular inspections of the hoist, trolley, rails, and structural integrity are essential. Lubrication, electrical checks, and replacement of worn parts are common maintenance tasks.

4. Can gantry cranes be customized?

Absolutely. Gantry cranes can be tailored to meet specific needs, such as custom lifting capacities, spans, and mobility features.

5. How are gantry cranes powered?

Most gantry cranes are powered electrically, though some smaller or portable models may use manual or hydraulic systems.

Gantry cranes are indispensable tools for heavy lifting and material handling across various industries. Their mobility, versatility, and high load capacities make them a popular choice for both indoor and outdoor applications. By understanding the types, features, and applications of gantry cranes, you can determine the best crane for your specific needs.