What is the anchor of a cargo ship?

Cargo ship anchors are critical components of maritime operations, ensuring ships remain stationary during docking, waiting, or when encountering unfavorable weather conditions. Anchors play a vital role in safety and stability on the water. Let’s delve into the types of ship anchors, their materials, weight considerations, and proper usage techniques .

Types of Cargo Ship Anchors

1- Stockless Anchor

- Description: The most common type of anchor found on modern cargo ships. It has a curved design and no protruding stock (the crossbar). This feature allows for easier stowing.

- Usage: Ideal for deep-water and harbor anchoring, stockless anchors hold well in most seabeds, particularly sand, mud, or clay.

- Weight: Varies from 1 to 30 tons, depending on the ship’s size.

2-Chetteral Anchor

- Description: A heavy-duty, all-steel anchor with a fluke that grips the seabed tightly. Its design allows for excellent holding power in various seabeds.

- Usage: Best used for vessels operating in rocky or variable seabed conditions.

- Weight: Typically between 5 and 25 tons.

3- Plough Anchor

- Description: This anchor is shaped like a plough and is designed to dig into the seabed when dropped. It has high holding power and is effective for harsh seabeds.

- Usage: Suitable for shallow waters and muddy or sandy conditions.

- Weight: Can range from 1 to 15 tons.

4- Hall Anchor

- Description: A variant of the stockless anchor, it has a more refined design for better performance in the toughest environments. Known for its fast and easy deployment.

- Usage: Primarily used on vessels that operate in rough seas and require swift, secure anchorage.

- Weight: Ranges between 5 and 30 tons.

5- Fisherman’s Anchor

- Description: A traditional design, these anchors feature two flukes that help hold the ship in place by hooking into the seabed.

- Usage: Typically used for smaller vessels or ships in harbors or shallow waters. They offer excellent reliability for short-term anchoring.

- Weight: Varies, typically between 1 to 8 tons.

Materials Used in Cargo Ship Anchors

- Steel: The most common material due to its strength and corrosion resistance. It is used in all types of anchors, ensuring durability in harsh marine conditions.

- Grades: Anchors are often made from high-quality steel like ASTM A36 or AISI 316 to withstand marine corrosion.

- Aluminum: Sometimes used in lighter-duty anchors due to its reduced weight and resistance to corrosion. However, it is not as strong as steel, so it is less common in larger vessels.

- Galvanized Steel: Steel anchors are frequently galvanized to provide extra protection from corrosion. The galvanization process involves coating the steel with a layer of zinc.

Weight Considerations for Cargo Ship Anchors

The weight of an anchor is crucial to its holding power. The correct weight is determined by the size of the ship, the type of anchor, and the environmental conditions. A heavier anchor typically offers better holding power, but it must be balanced with the vessel’s design and operational needs.

- Lightweight Anchors: Suitable for smaller vessels, typically weighing between 500 kg to 5 tons.

- Medium Anchors: Found on mid-sized ships, usually weighing between 5 and 20 tons.

- Heavy Anchors: For large cargo vessels, weighing anywhere from 20 tons to more than 30 tons, depending on the ship's size.

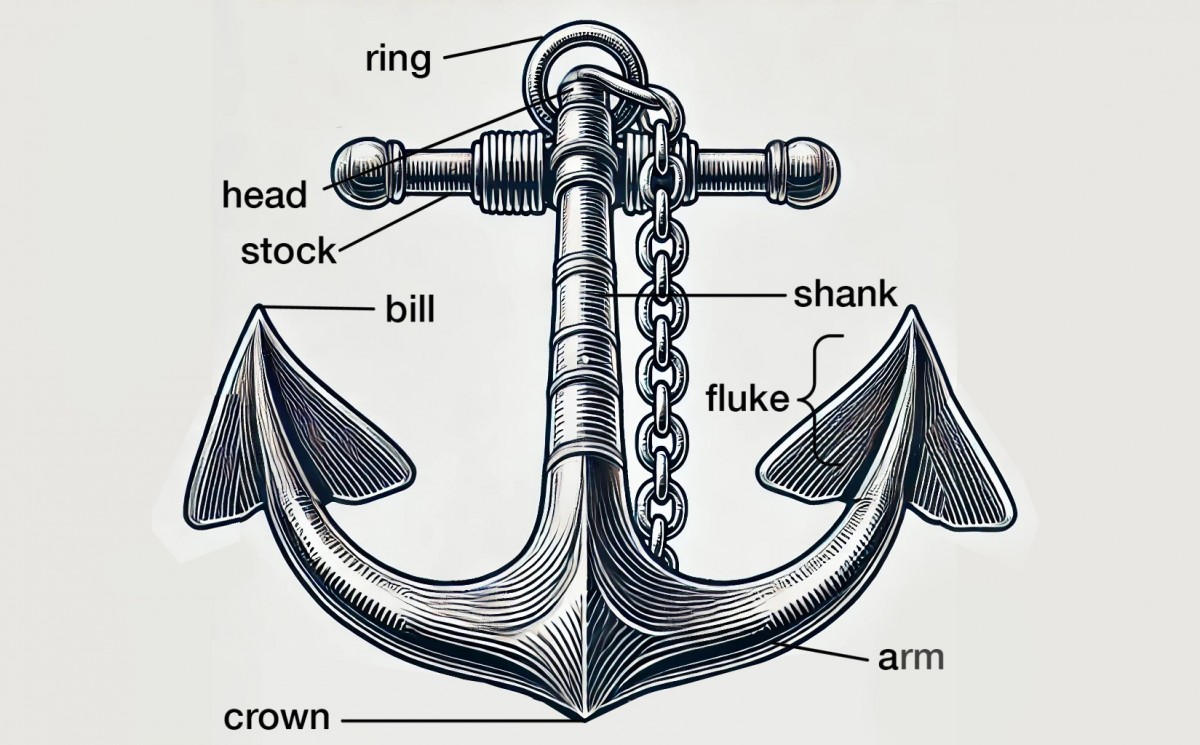

Parts of an Anchor Explained

- Ring: The top loop of the anchor where the chain or rope attaches to connect the anchor to the ship.

- Head: The top end of the shank, often near the ring.

- Stock: A horizontal bar attached to the shank just below the head. It helps the anchor turn and dig into the seabed properly.

- Shank: The long, vertical shaft that connects the stock to the arms and flukes. It is the main body of the anchor.

- Balancing Band: A ring or strap around the shank for stabilizing the anchor while hoisting.

- Fluke: The pointed part of the anchor, consisting of both the bill and the palm, designed to dig into the seabed to hold the anchor in place.

- Bill: The sharp end of the fluke, which helps the anchor catch onto the seabed.

- Palm: The flat surface of the fluke that helps with gripping the ground.

- Crown: The area at the bottom of the shank where the arms branch out. It allows the anchor to pivot and adjust its position.

- Arm: The curved sections that extend from the crown and end in flukes. The arms hold the flukes in place as they dig into the ground and stabilize the anchor

How to Use a Cargo Ship Anchor

- Preparation: Before dropping anchor, ensure the anchor chain or cable is fully deployed, and the anchor is ready to be released. Most modern ships have a windlass to lower the anchor.

- Deployment: Drop the anchor to the seabed, ensuring it digs into the sediment. The anchor's flukes or ploughs should immediately begin to hold the vessel in place.

- Holding the Ship: After the anchor is deployed, the ship should remain stationary as the anchor holds in place. If the ship drifts, the anchor may not have dug in properly, and adjustments will be needed.

- Retrieving the Anchor: When it’s time to move, the anchor is raised using the windlass. The anchor chain is pulled back aboard the ship, and the anchor is secured for the next operation.

Key Considerations for Effective Anchor Use

- Water Depth: In deeper waters, longer anchor chains or cables are required. Typically, the ratio of chain to depth is 5:1, meaning for every meter of water depth, 5 meters of chain are needed.

- Seabed Conditions: Choose the anchor type based on the seabed. Muddy and sandy seabeds are easier to hold, while rocky or hard grounds require anchors designed to grip firmly.

- Weather Conditions: Strong currents and winds may affect the anchor’s ability to hold. In such cases, using a second anchor or increasing the length of the anchor chain can improve stability.

The Heaviest Ship Anchors and Their Vessels

The weight of an anchor is crucial in determining its holding power and suitability for different types of vessels. The heaviest anchors are typically found on large cargo ships, oil tankers, and large container ships, where stability and security are paramount.

Heaviest Anchor Types

- Stockless Anchors: These anchors are often among the heaviest and are used on larger vessels due to their efficiency and ability to hold well in various seabed conditions. Stockless anchors can weigh up to 30 tons or more, depending on the size of the ship.

- Plough Anchors: Known for their ability to dig deeply into the seabed, plough anchors used on larger vessels can weigh up to 30 tons as well.

- Chetteral Anchors: These anchors are also used on large vessels and can weigh over 25 tons for deep-water anchoring.

Vessels Using the Heaviest Anchors

- Large Cargo Ships: Cargo ships, especially those over 100,000 gross tons (GT), require very heavy anchors to ensure they remain stationary during loading and unloading, or in the case of severe weather. These vessels often use stockless or plough anchors that weigh between 20 and 30 tons or more.

- Oil Tankers: Given their size and the need to anchor in rough seas or deep waters, oil tankers use heavy anchors, often exceeding 30 tons in weight, to ensure stability and safety in sensitive maritime operations.

- Container Ships: Container vessels, which can also be massive, require similarly heavy anchors to secure their massive tonnage. The weight of the anchors for these ships can reach up to 30 tons, depending on their size and operation requirements.

- LNG Carriers: Liquefied Natural Gas (LNG) carriers, which are specialized and large, require heavy-duty anchors, typically weighing between 25 and 30 tons, to secure their position in rough seas during LNG loading or unloading operations.

The weight of these anchors is directly proportional to the size and operational demands of the ship. Larger vessels require more substantial anchoring systems to ensure they can stay in position, even under harsh environmental conditions.

Choosing the right cargo ship anchor and understanding its proper use is essential for safety and efficiency in maritime operations. Whether you're a shipping company or an operator, having detailed knowledge of anchor types, materials, and usage will enhance your operational capabilities and ensure your vessels are securely anchored in any environment.